Forums » Discussion and support »

Configuring LAOS

Configuring LAOS

Added by peteruithoven over 12 years ago

I finally converted our second, bigger lasercutter (Morntech) to LAOS. The nice thing is that you can switch it from closed source to open source.

This works trough a simple "parallel port switch" that reroutes which hardware controles the motors and the laser etc.

This means we can now control it using the LAOS laser hardware and VisiCut and still have Coreldraw and the old electronics as backup.

Configuration was quite a bit of work, so hopefullu by documenting it we can clarify this. Because there are quite some holes in my understanding I'm not putting it in the wiki just yet, but when more is clear I will.

min, max, speed

Ignored them as already advised

pol & homedir

I started with the axis pol and homedir to get the homing working. The descriptions for these are quite clear.

scale

Then there is the scale of both axis. My trick was to draw a 10x10mm rectangle and tweak the scale untill the lasercutted square was 10x10mm. If there is a way to calculate this or look this up please let me know than I can document this a bit better.

invert

Still don't understand this one, did quite some tests but it didn't seem to matter on my lasercutter. Please clarify.

home & rest

I noticed that my rectangle was lasercutted in the right size, but the position was way off.

Not quite sure how this one works. But by trail and error I got it right. It somehow influences the start position. The most confusing this that half way I figured out it was lasercutting the mirrored over the Y axis. As documented I had to invert the scale (so -45000 instead of 45000) but this only worked with a different home position, otherwise it tried to move past the endstops.

I had a "Hello world" text positioned 10x10mm from top left in Visicut and tweaked the home position untill it actually lasercutted it at 10x10mm.

If someone can point me into the direction of the logic, I would be happy to document it on the wiki.

pwm settings

I then tweaked the pwm.min and pwm.max to get the best range. From lasercutting as subtle as possible with power 1 to lasercutting max at power 100. When you have the max at 255 I noticed that 1/3 cutted at the same depth, so I ended up with 165 which gave me a nice range.

My testpattern laserscript was a great help in this.

Because you have to restart the LAOSlaser to get it to reread the config file and the first time you send a file it fails tweaking is quite combersome. I'll add a feature request for a "update config" menu item.

I also added my current config file.

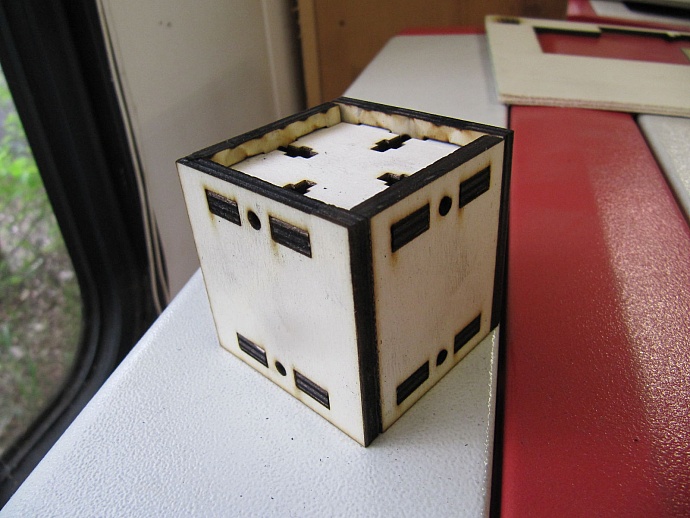

| switch.jpg (4.5 KB) switch.jpg | |||

| config.txt (2.51 KB) config.txt | |||

| engrave.jpg (133 KB) engrave.jpg | |||

| cutting.jpg (130 KB) cutting.jpg | |||

| openclosed.jpg (171 KB) openclosed.jpg |

Replies (9)

RE: Configuring LOAS

-

Added by peteruithoven over 12 years ago

RE: Configuring LOAS

-

Added by peteruithoven over 12 years ago

Small update.

Sometimes (usually everytime except the first job) the lasercutter started by cutting a big line from top to bottom before executing the actual job.

I found out what it was. In the Visicut lasercutter settings xml there is a flipYaxis value. This was set to true.

Now the settings make more sense. The y.home and y.rest position are actually the distance (in um) to the home/rest position from the endswitch. Because the endswitch is at the top it's simply 0.

The y.scale is now 45000 instead of -45000.

RE: Configuring LOAS

-

Added by jaap over 12 years ago

RE: Configuring LOAS

-

Added by jaap over 12 years ago

Hi Peter,

In LaOS, the standard is to have the (0,0) point in the lower left corner. The way you configure your machine now, it is in the upper left corner.

Of course, you are free to changes settings any way you want, but this is not the LaOS default and will be confusing for others.

So your small update is not correct: flipYaxis should be true in Visicut (this is the default). y.home = a high number, and y.rest too. They should not be 0.

Jaap

RE: Configuring LOAS

-

Added by peteruithoven over 12 years ago

RE: Configuring LOAS

-

Added by peteruithoven over 12 years ago

After an enlightening talk with Jaap I updated the wiki. I tried to make everything dummy proof, because the one configuring the lasercutting might not know about motor control (I don't for example). I also tried to elaborate on the process of configuring it.

Armed with the new knowledge I'll try again with our bigger lasercutter and see if I still get the start line issue.

RE: Configuring LOAS

-

Added by peteruithoven over 12 years ago

RE: Configuring LOAS

-

Added by peteruithoven over 12 years ago

Okay another interesting observation. I measured the horizontal and vertical distance the laser head could move and used that as x.home and y.home setting. But cutted my drawing (placed at 0,0 using VisiCut) lower than 0,0.

This was caused by the Yflip trick and the fact that the bed height setting of my lasercutting was lower. The bed height should be the same distance as the y.home (but then in mm instead of um).

RE: Configuring LAOS

-

Added by jaap over 12 years ago

RE: Configuring LAOS

-

Added by jaap over 12 years ago

OK, for the next version... maybe Visicut could query the laser for values like this?

A simple implementation would be that Visicut reads a standard file via TFTP, for example it asks for config.txt. It doesn't work now, but we could adapt the TFTP server to send back the current configuration (either "from file" or by creating it from the current settings in memory).

RE: Configuring LOAS

-

Added by peteruithoven over 12 years ago

RE: Configuring LOAS

-

Added by peteruithoven over 12 years ago

Shame. Did it the way it should be done, but now our big lasercutter cuts this long vertical line from top to bottom before it starts the job. This happens every time except the first time. The strangest thing is that this doesn't happen on our smaller lasercutter.

They both use a firmware version from 29 dec 2012.

The only difference I can think off is the placement of the x endswitch. Maybe left placed horizontal switches aren't properly supported yet.

I've put the config files of both lasercutters on the "overview page":

http://redmine.laoslaser.org/projects/laos/wiki/A_list_of_users_with_LAOS_converted_lasercutters and added them to this post.

RE: Configuring LAOS

-

Added by jaap over 12 years ago

RE: Configuring LAOS

-

Added by jaap over 12 years ago

Curious to see the beginning of your SimpleCode file. Can we blame Visicut, or is it something in the firmware?

RE: Configuring LAOS

-

Added by peteruithoven over 12 years ago

RE: Configuring LAOS

-

Added by peteruithoven over 12 years ago

That would be nice. But at the moment this only plays when someone is configuring the lasercutter. I think there are more important issues.

I created a block (10x10mm) and placed it 10x10mm from the top left in VisiCut. And I generated the files for our small and big lasercutter. The simplecode I have is given to me trough the Debug output file function in VisiCut.

There is little difference between the files except from the y distance.

| small.txt (114 Bytes) small.txt | |||

| big.txt (113 Bytes) big.txt | |||

| simplecode preview small.png (21.6 KB) simplecode preview small.png | |||

| simplecode preview big.png (21.8 KB) simplecode preview big.png |

RE: Configuring LAOS

-

Added by peteruithoven over 12 years ago

RE: Configuring LAOS

-

Added by peteruithoven over 12 years ago

I improved Rick Companje's Simplecode previewer to make it easier to visually check simplecode files.

| simplecode.zip (3.03 KB) simplecode.zip |